Ferrocement concrete is a composite material widely recognized for its strength, versatile applications, and cost-effectiveness. Unlike traditional concrete, which relies on coarse aggregates, ferrocement uses fine aggregates and reinforced wire mesh, leading to a dense and durable material. Here, the composition, applications, and advantages of ferrocement are discussed.

Composition and Structure of Ferrocement

- Cement: Ordinary Portland Cement is used as the binder.

- Fine Aggregates: Sand, which provides the necessary bulk and strength.

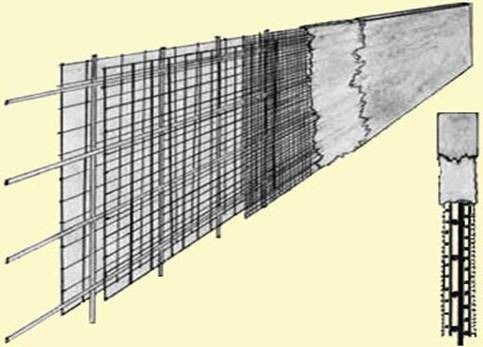

- Wire Mesh/Reinforcement: Layers of wire mesh or metallic fibers, which significantly enhance tensile strength and ductility.

- Water: Essential for the hydration process and workability.

- The wire mesh is placed in multiple layers, and the cement-sand mortar is applied over it, ensuring that the mesh is entirely encapsulated.

Read Also- Lightweight Concrete – Making And Applications

Applications of Ferrocement Concrete

Ferrocement finds a wide range of applications due to its unique properties:

- Building Components: Prefabricated panels, roofs, walls, and floor slabs benefit from its strength and ease of fabrication.

- Repair Works: Reinforcement of damaged or deteriorated concrete structures.

- Marine Structures: Ideal for boats, barges, and even underwater structures due to its impermeability and resistance to marine conditions.

- Architectural Elements: Sculptures, decorative facades, and architectural panels leverage its ability to be molded into complex shapes.

- Water Tanks: Used in the construction of robust and leak-proof water storage tanks.

Advantages of Ferrocement Concrete

Ferrocement Concrete offers numerous advantages over traditional construction materials:

- High Strength-to-Weight Ratio: The wire mesh reinforcement provides high tensile strength while keeping the material lightweight.

- Durability: Resistant to cracking, corrosion, and impact, leading to long-lasting structures.

- Versatility: Easily molded into various shapes and sizes, allowing for innovative architectural designs.

- Cost-Effectiveness: Requires less material and labor compared to conventional reinforced concrete.

- Sustainability: The use of fine aggregates and minimal concrete makes it an environmentally friendly option.

Challenges for Ferrocement Concrete

- Labor-Intensive: The placement of wire mesh and the application of mortar require skilled labor.

- Quality Control: Ensuring the uniform encapsulation of the wire mesh and proper curing is essential for optimal performance.

- Limited Awareness: Not as widely recognized or adopted as conventional construction methods, particularly in regions with well-established construction practices.

Final Words:

Ferrocement concrete has a vast potential to impact the construction industry. hanger in the construction industry, offering a blend of strength, durability, and versatility that few materials can match. Its potential for innovative applications and sustainable construction makes it a material worth considering for modern construction projects. As awareness and expertise grow, we can expect to see even more groundbreaking uses for ferrocement in the future.

Read Also-

Different Methods of Concrete Curing – Concrete Technology

Cellular Lightweight Concrete – Materials and Applications

Basalt Fiber Reinforced Concrete: Promising Material

Ground Granulated Blast Furnace Slag (GGBS) Applications in Concrete