Fibre Reinforced Polymer (FRP) rebar combines high-performance polymers with continuous fibres to deliver superior tensile strength, corrosion resistance, and lightweight properties. As infrastructure owners demand longer service lives and reduced maintenance, FRP rebar emerges as an appealing alternative to traditional steel reinforcement.

Composition and Types of FRP Rebar

Fibre Reinforced Polymer rebar consists of two main components:

- Fibres

- Glass (GFRP)

- Carbon (CFRP)

- Basalt (BFRP)

- Polymer Matrix

- Epoxy

- Vinylester

- Polyester

The choice of fibre and matrix dictates mechanical properties, durability, and cost. Glass offers cost-effectiveness, carbon provides exceptional stiffness, and basalt strikes a balance between performance and price.

Key Mechanical and Physical Properties

FRP rebar exhibits distinctive characteristics compared to steel:

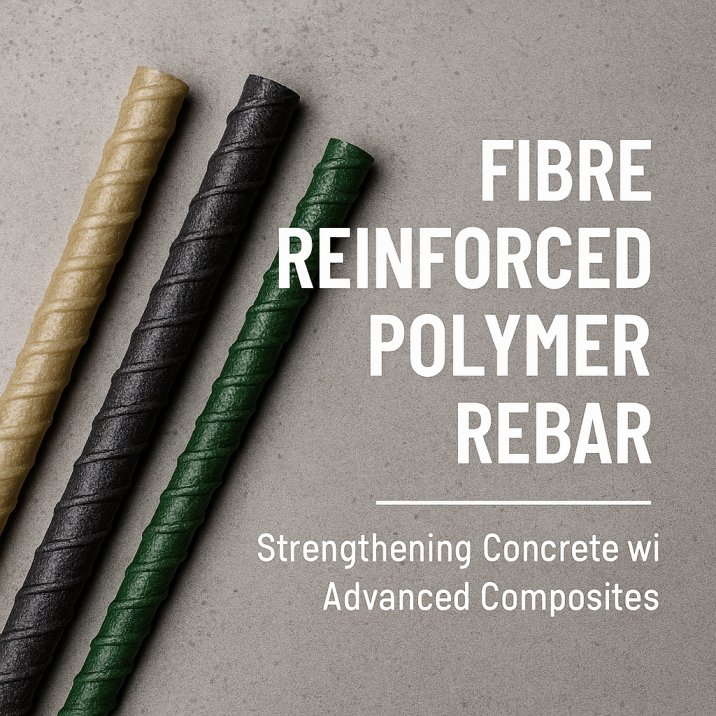

| Type | Color | Surface Texture | Material |

|---|---|---|---|

| GFRP | Beige | Helical ribs, textured | Glass Fibre |

| CFRP | Dark Gray / Black | Helical ribs, smooth texture | Carbon Fibre |

| BFRP | Green | Helical ribs, textured | Basalt Fibre |

Manufacturing Process of Fibre Reinforced Polymer Rebar

- Fibre Impregnation Continuous roving or fabric is saturated with resin in a pultrusion bath.

- Shaping and Curing Pultrusion dies shape the rebar’s ribbed profile; heat or UV initiates curing.

- Post-Processing Surface embossing improves bond strength with concrete; quality control checks tensile and dimensional tolerances.

Bond Behavior and Anchorage

Achieving adequate bond between FRP and concrete is critical. Unlike steel, FRP’s lower stiffness can lead to slip under load. Common approaches to improve bond include:

- Surface Deformations (ribs or sand coating)

- Helical wraps or near-surface grooves

- Mechanical anchorage with end anchors

Design guidelines (e.g., ACI 440.1R) provide empirical bond coefficients to calculate development length.

Advantages of FRP Rebar

- Corrosion immunity in chloride-rich or aggressive environments

- High strength-to-weight ratio reduces handling costs

- Non-magnetic and dielectric—ideal for sensitive structures

- Lower thermal conductivity minimizes thermal bridging

Limitations and Design Considerations

- Linear elastic behavior up to failure—no yielding plateau

- Lower modulus can lead to larger crack widths under service loads

- UV and high-temperature exposure may degrade polymer matrix

- Higher initial material cost vs. conventional steel

Engineers must account for serviceability, fatigue performance, and compatibility with existing codes.

Codes, Standards, and Design Guidelines for FRP Rebars

Key references for FRP-reinforced concrete design include:

- ACI 440.1R-15: Guide for the Design and Construction of Concrete Reinforced with FRP Bars

- CSA S6-14: Canadian Highway Bridge Design Code (FRP provisions)

- ISO 10406-1: Carbon Fibre Reinforced Polymer Rebars

These documents establish partial safety factors, bond coefficients, and allowable strain limits.

Applications and Case Studies

- Marine Structures: Offshore platforms and piers benefit from corrosion resistance.

- Bridge Decks: GFRP grids reduce dead load, extend deck life, and simplify maintenance.

- Parking Garages: Chloride exposure from de-icing salts accelerates steel corrosion; FRP bars mitigate this.

- Architectural Panels: Non-conductive properties enable embedded sensors and heating elements.

Example: A coastal footbridge in Florida replaced steel bars with GFRP, achieving a 25% reduction in deck thickness and zero corrosion-related repairs over 10 years.

Future Trends and Research Directions for FRP Rebars

- Hybrid Bars combining FRP and steel cores to merge ductility and corrosion resistance.

- Bio-based Resins derived from vegetable oils to enhance sustainability.

- Embedded Monitoring through fibre-optic sensors for real-time strain and temperature sensing.

- Recyclability improvements enabling end-of-life material recovery.

Conclusion

Fibre Reinforced Polymer rebar represents a transformative reinforcement strategy for modern concrete structures. Its corrosion immunity, high tensile strength, and lightweight characteristics position FRP as a solution for infrastructure resilience. However, designers must integrate specialized bond treatments, account for linear elastic behavior, and adhere to emerging codes. As research advances—through hybrid composites, sustainable resins, and smart sensing—FRP rebar will continue to redefine best practices in structural engineering.

Read Also-

Top 10 Construction Companies in the USA – (2025 edition)

Top 10 Civil Engineering Colleges in the USA – 2025

Download Building Codes-