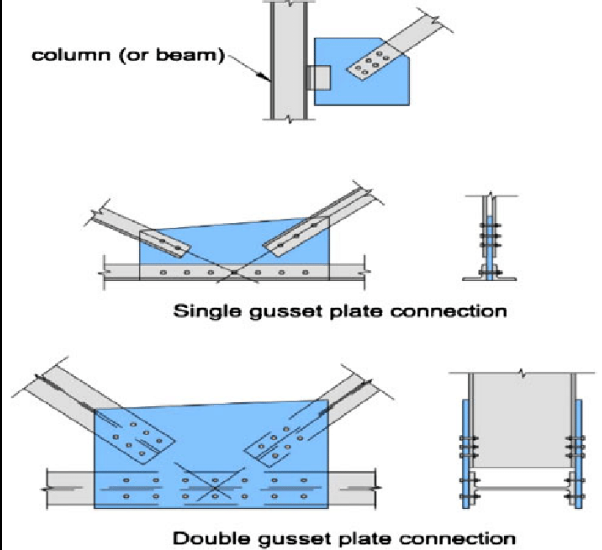

In steel structures, as in an RCC structure, some common types of connections are beam to column connections, beam to beam connections, connections of transverse stiffeners with the beam, connections of lacing and battening in the columns, the connections of column with foundation. It is a very common practice to use a gusset plate for connections more than two elements in the steel structures.

In steel structures, the connections are either made with bolting and riveting or by welding.

Bolted Connections

How bolted connections should be fabricated and its guidelines are described in IS 800: 2000. Most commonly used connections with bolted joints are lap joint, single cover butt joint, double cover butt joint, etc.

Advantages of Bolted Connections

- Bolted connections are easy to erect and no skilled labor is required.

- With a bolted connection, it is easy to erect and fabricate structures faster than welded connection.

- It is easy to dismantle the structure made with bolted connections.

Disadvantages of Bolted Connection

- In bolting and riveting the effective area of the structural member is reduced and thus it should be considered in the design.

- Sometimes, while using black bolts there is slippage of connection.

- Bolted connections are not watertight.

- Usually, bolted connections degrade the aesthetic of the structure.

- Bolted connections are difficult to paint.

Welded Connections

Welded connection is preferred over bolted connection when there is a need to prevent aesthetic of the structure. They are costlier and need skilled labor. Generally welded connections are either of these four types, 1) Plug weld, 2) Fillet weld, 3) Slot weld, and 4) Butt weld. Fillet welds are the most widely used welded connection in steel structures.

Advantages of Welded Connection

- They are useful when needed to achieve beauty and aesthetics.

- They are watertight and give a pleasant appearance to the steel structure.

- It is easy to color and paint the welded connection.

- Welded connections can be made with little noise.

Disadvantages of Welded Connection

- These type of connections are costlier and needs skilled labor for fabrication.

- The technology used in these types of connections is costlier and difficult to erect compared with the bolted connections.

- Welded Connections are hard to inspect.

Further Related Readings-

IS 800 2007 [PDF-Download] Code of practice for design of steel structure

SP 6 Steel Structures Handbook Download [PDF]

IS 875 Code to Calculate Load (PDF Download)

You can also refer to course on steel structures by NPTEL IIT Kharagpur

FAQs

HSFG means High Strength Friction Grip Bolts.