In the ever-evolving world of construction, materials that offer enhanced performance and sustainability are highly sought after. Glass Fiber Reinforced Concrete (GFRC) is one of such material that has gained significant attention of civil engineers. This new composite material combines the versatility of concrete with the strength of glass fibers, resulting in a product that is both durable and adaptable.

What is Glass Fiber Reinforced Concrete?

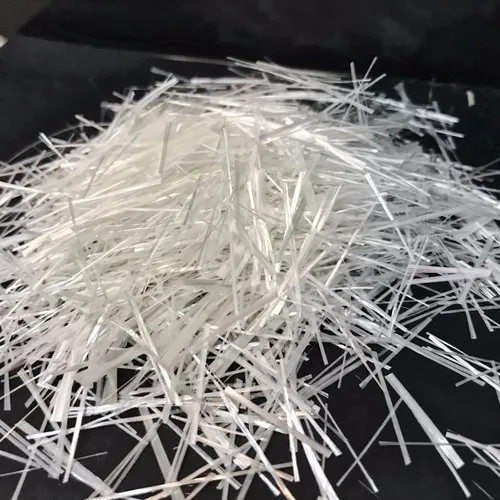

Glass Fiber Reinforced Concrete (GFRC) is a type of fiber-reinforced concrete that incorporates specially engineered glass fibers into the concrete mix. These fibers are made from alkali-resistant glass, which ensures they do not deteriorate in the highly alkaline environment of concrete. The result is a composite material with improved compressive, flexural, and tensile strength.

Benefits of Glass Fiber Reinforced Concrete

- Lightweight: GFRC is significantly lighter than traditional concrete, making it easier to handle and install. This property is particularly beneficial for architectural elements and cladding panels.

- High Strength: The inclusion of glass fibers enhances the tensile and flexural strength of the concrete, making it more resistant to cracking and deformation.

- Durability: GFRC is highly durable and can withstand harsh environmental conditions, including freeze-thaw cycles and chemical exposure.

- Versatility: GFRC can be molded into a variety of shapes and sizes, allowing for intricate designs and detailed architectural features.

- Crack Control: Glass Fibers help control shrinkage cracking, limiting the formation and spread of cracks within the structure, thereby enhancing its durability. Glass Fibers serves as bonding material and distributes stress.

- Sustainability: By reducing the amount of cement required and utilizing recycled glass fibers, GFRC contributes to more sustainable construction practices.

Applications of GFRC

GFRC is used in a wide range of applications, including:

- Architectural Cladding: GFRC panels are commonly used for building facades, providing an attractive and durable exterior finish.

- Decorative Elements: The material’s versatility allows for the creation of intricate decorative features such as columns, cornices, and sculptures.

- Infrastructure Projects: GFRC is used in the construction of bridges, tunnels, and other infrastructure projects where high strength and durability are essential.

- Interior Design: GFRC is also used for interior applications, including countertops, sinks, and furniture, due to its aesthetic appeal and durability.

Also Read- Methods of Concrete Curing – Concrete Technology

Challenges and Considerations

While GFRC offers numerous benefits, there are some challenges to consider:

- Cost: The production of GFRC can be more expensive than traditional concrete due to the cost of glass fibers and specialized manufacturing processes.

- Technical Expertise: Proper mixing, handling, and installation of GFRC require technical expertise to ensure optimal performance.

- Quality Control: Ensuring consistent quality in GFRC production is crucial, as variations in the mix can affect the material’s properties.

Conclusion

Glass Fiber Reinforced Concrete (GFRC) represents a significant advancement in construction materials, offering a combination of strength, durability, and versatility. Its applications range from architectural cladding to intricate decorative elements, making it a valuable addition to modern construction projects. As the industry continues to prioritize sustainability and performance, GFRC is poised to play a crucial role in shaping the future of construction.

If you have any question on GFRC then feel free to comment. And don’t forget to share.

Also Read-

Basalt Fiber Reinforced Concrete: Promising Material

Ground Granulated Blast Furnace Slag (GGBS) Usages in Concrete