Broadly there are two different types of stone masonry, namely Ashlar Masonry and Rubble Masonry.

Table of Contents

Ashlar Masonry

This Masonry is more attractive and pleasant looking than rubble masonry. Ashlar masonry uses well-prepared and regular shape stones. Ashlar Masonry could be divided into the following six types.

- Ashlar Fine

- Ashlar Rough tooled

- Ashlar Quarry Faced

- Ashlar Chamfered

- Ashlar Facing

- Ashlar block in course

Rubble Masonry

This type of stone masonry uses irregular shapes and sizes of stone. The strength of rubble masonry highly depends on the mortar used for construction. In rubble masonry, the stones brought from quarry are prepared with hammers or sometimes used without preparation.

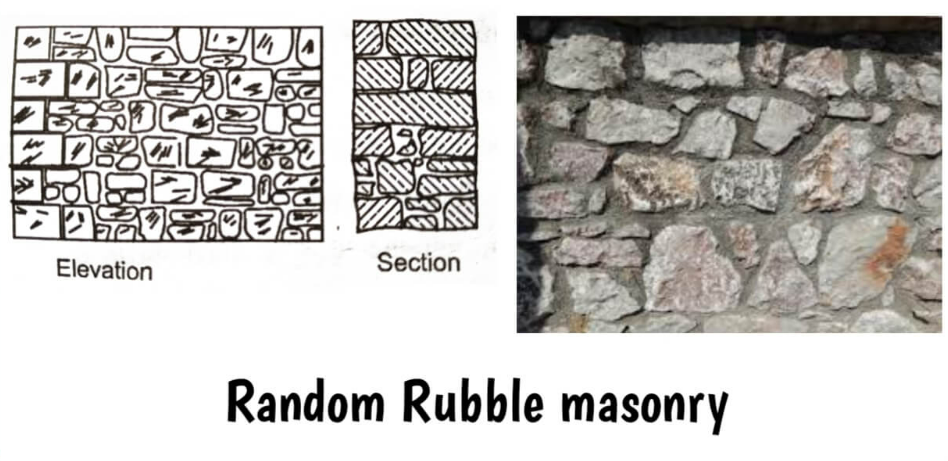

Random Rubble Masonry

Random Rubble Masonry uses stones of irregular shapes and sizes. This type of masonry costs moderately low and is used for low-cost residential buildings and warehouses.

Dry Rubble Masonry

This type of masonry uses irregular shapes of stone for construction without the use of mortar. Dry rubble masonry is comparatively cheaper and does not require especially skilled labor. This one is used to create boundary walls.

Read Also- Types of Cement, Their Properties and Applications

Coursed Rubble Masonry

This type of masonry gives a good aesthetic view with a somewhat higher cost and needs skilled labor.

Un-coursed Rubble Masonry

An un-coursed rubble masonry is the cheapest and roughest form of stone masonry construction. These constructions use stones of varied shapes and sizes.

Polygonal Rubble Masonry

Here, the stones for masonry are roughly shaped into irregular polygons. The stones are then arranged in such a way that it avoids vertical joints in the face work.

Flint Rubble Masonry

In Flint Rubble Masonry, the stones are not cut and shaped to uniform dimensions but are used in their natural shape and irregular form. This type of stone masonry gives an aesthetic look but requires skilled labor.

Joints in Stone Masonry

Joints are an essential part of construction. The following types of joints are used in stone masonry to interlock stones with each other.

- Butt or Squared Joint

- Lap or Rebated Joint

- Plugged Joint

- Table Joint

- Joggle or Tonged and groove joint

- Dowel Joint

- Camp Joint

Read Also- Criteria For Selection Of The Repair Material

Advantages of Stone Masonry

Stone masonry comes with inherited advantages. Some of these advantages are discussed below.

- Aesthetic Appeal: Stone masonry offers a timeless and aesthetically pleasing look. The natural textures, colors, and variations in stone can add a unique and charming character to any structure. This is particularly important for heritage and high-end construction projects.

- Durability and Longevity: Stone structures are renowned for their exceptional durability. They can withstand harsh weather conditions, resist fire, and remain stable over time. Many ancient stone buildings and monuments still stand today as a testament to their longevity.

- Thermal Mass: Stone has a high thermal mass, which means it can absorb, store, and slowly release heat. This can help regulate indoor temperatures and contribute to energy efficiency by reducing the need for constant heating or cooling.

Disadvantages of Stone Masonry

- Cost: Stone masonry can be more expensive than other building methods due to the skilled labor required, the effort in sourcing and preparing stones, and the time-consuming construction process.

- Weight and Structural Considerations: Stone structures are heavy, which means foundations and structural support need to be designed to handle the load. This can increase the complexity and cost of the overall project.

- Maintenance Challenges: While stone masonry requires less maintenance than some materials, repairs, and replacements can be intricate and costly. Over time, weathering and erosion can affect the appearance and structural integrity of stone structures.

Read Also- Bricks & Brick Masonry [Building Construction]

Things to consider in stone masonry

- Trough stone should be used where necessary.

- The mortar used to fill joints should be of superior quality.

- The stones being used in construction should be free from defects like cavities and cracks.

- Curing of the masonry should be done till two weeks after completing construction.

Tools used in Stone Masonry

- Chisels – These are essential in stone masonry. Chisels are used to split and cut the stones and to give stones proper shape. Chisels come in various shapes and sizes.

- Saws – These are used to cut the stones in desired shapes and sizes.

- Hammers – These are used to strike chisels.

- Levels and Squares – These are used to align stones in proper positions.

- Trowels – These are used to apply mortars in joints.

- Drills – Masonry drills are used to create holes in the stones.

- Lifting and Handling Tools – Lifting tools like stone clamps, hoists, and hoists are used to safely move the stones.

Read Also-

Causes, Effects, and Remedies of Dampness in Building

Different Types of Paints Used In Construction

Different Types of Windows – Building Construction

External Resources-

https://www.sciencedirect.com/topics/engineering/stone-masonry